Field and Simulation Studies for Mechanised Depillaring below Incompetent Geological Formations of an Indian Coal Mine

DOI:

https://doi.org/10.1007/s12594-021-1698-yKeywords:

No keywords.Abstract

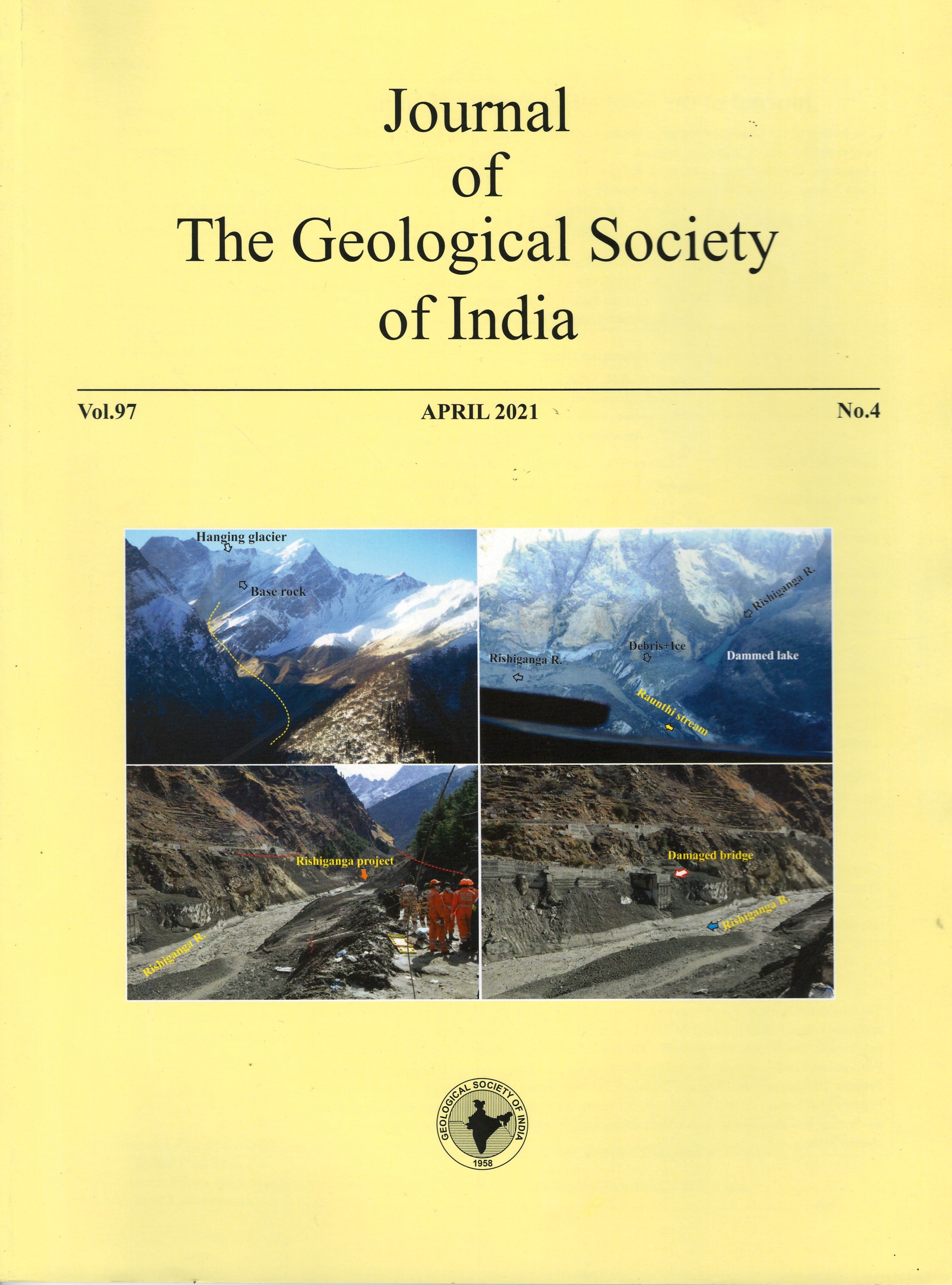

A fully mechanised mining method using continuous miner (CM) for pillar extraction in single-pass is introduced in the year 2010 at Pinoura Mine of South Eastern Coalfields Limited, Bilaspur in India. Overall mining cycle time is reduced by singlepass pillar extraction as it does not require drivage of split galleries in pillars and support installation for such galleries. Further, inherent technical abilities of the deployed CM for faster cutting and quad-bolter for supporting, helped in faster recovery of pillars without creating any strata control issues. Rate of face advance varied between 5-15m/day with an average of 8m/day. Field observations found that CM based single-pass extraction is capable in dealing with the strata control issues during depillaring under weak and laminated (incompetent in nature) roof layers having rock mass rating value around 42. A total of eleven panels, have been depillared under the weak and laminated geology, ranging depth of cover from 59 to 149m in different panels of the mine. During field investigations in these panels, a maximum of 2.89MPa induced vertical stress is recorded and influence of caved roof over underground mining structures is observed up to 15m in the outbye from the goaf edge. This paper deals with estimation of snook size and limiting roof movement value based on numerical simulation and field studies during the single-pass extraction below the incompetent geological formations.

Downloads

Metrics

Issue

Section

Downloads

Published

How to Cite

References

Bieniawski, Z.T. (1976) Rock mass classifications in rock engineering. In: Bieniawski ZT (Ed.), Exploration for Rock Engineering, (Balkema, Rotterdam), v.1, pp.97-106.

Chase, F.C., Mark, C., Heasley, K.A. (2002) Deep cover pillar extraction in the U.S.A. In: Proc. 21st Int. Conf. Ground Control in Mining. Morgantown, WV, USA, pp.68–80.

CIMFR Report (2011). Designing pillar extraction method using Continuous Miner in Pinoura Mine, Johila Area, SECL by Central Institute of Mining and Fuel Research- Regional Centre, Nagpur, Project no. CNP/2685/2010- 11.

Helm, P.R., Davie, C.T., Glendinning, S. (2013) Numerical modelling of shallow abandoned mine working subsidence affecting transport infrastructure. Eng. Geol., v.154, pp.16-19.

Itasca (2007). Itasca Consulting Group, Inc., FLAC2D (Fast Lagrangian Analysis of Continua in 2 dimensions). Version 4.0. Minneapolis, MN.

Itasca (2012). Itasca Consulting Group, Inc., FLAC3D (Fast Lagrangian Analysis of Continua in 3 dimensions). Version 5.0. Minneapolis, MN.

Kumar, A., Kumar, D., Singh, A.K., Ram, S., Kumar, R., Gautam, A., Singh, R., Singh, A.K. (2019) Roof sagging limit in an early warning system for safe coal pillar extraction. Int. Jour. Rock Mech. Min. Sci., v.123, art. no.104131.

Kumar, A., Kumar, D., Verma, A.K., Singh, A.K., Ram, S., Kumar, R. (2018) Influence of overlying roof strata on rib design in mechanised depillaring. Jour. Geol. Soc. India, v.91, pp.341-347.

Kumar, R., Mishra, A.K., Singh, A.K., Singh, A.K., Ram, S., Singh, R. (2016) Depillaring of total thickness of a thick coal seam in single lift using cable bolts: A case study. Int. Jour. Min. Sci. Tech., v.26(2), pp.223-233.

Leeming, J. (2003) Joy introduce continuous miner: Technology into India. Coal International/Mining and Quarry World, pp.203-206.

Mark, C., Molinda, G.M. (2005) The Coal Mine Roof Rating (CMRR)-a decade of experience. Int. Jour. Coal Geol., v.64(1-2), pp.85-103.

Mohan, G.M., Sheorey, P.R., Kushwaha, A. (2001) Numerical estimation of pillar strength in coal mines. Int. Jour. Rock Mech. Min. Sci, v.38, pp.1185–1192.

Oldroyd, C., Bigby, D., Leeming, J. and Meyer, L. (2006) Successful application of rock bolt support and mechanised depillaring in difficult roof conditions at Tandsi mine, Western Coalfields, India. In: Proc. 25th International Conference on Ground Control in Mining, Morgantown, West Virgnia, pp.396-400.

Pappas, D., Mark, C. (2012) Roof and rib fall incident trends: A 10-year profile. Trans. Soc. Min. Metall. Explor., v.330, pp.462–478.

Ram, S., Kumar, D., Konicek, P., Singh, A.K., Kumar, R., Singh, A.K. and Singh, R. (2015) Rock mechanics studies during continuous miner-based coal pillar extraction in Indian coalfields. Transactions: A technical publication of the MGMI, India, v.111, pp.89-104.

Ram, S., Kumar, D., Singh, A.K., Kumar, A., Singh, R. (2017) Field and numerical modelling studies for an efficient placement of roof bolts a s breaker line support. Int. Jour. Rock Mech. Min. Sci., v.93, pp.152– 162.

Sarkar, S.K., Singh, B. (1985) Longwall Mining in India. Sunanda Sarkar, (Dhanbad), pp.237.

Sheorey, P.R. (1992) Pillar strength considering in situ stresses. Bur. Min., v.1, pp.122.

Singh R, Singh TN, Dhar BB (1996) Coal pillar loading for shallow mining conditions. Int. Jour. Rock Mech. Min. Sci. Geomech. Abstr., v.33(8), pp.757-768.

Singh, A.K., Kumar, A., Kumar, D., Singh, R., Ram, S., Kumar, R., Singh, A.K. (2020) Coal pillar extraction under weak roof. Accepted for publication in Mining, Metallurgy & Exploration in June 2020.

Singh, A.K., Singh, R., Maiti, J., Mandal, P.K., Kumar, R. (2011a) Assessment of mining induced stress development over coal pillars during depillaring. Int. Jour. Rock Mech. Min. Sci., v.48(5), pp.805-818.

Singh, R., Kumar, A., Singh, A.K., Coggan, J., Ram, S. (2016) Rib/snook design in mechanised depillaring of rectangular/square pillars. Int. Jour. Rock Mech. Min. Sci., v.84, pp.19-29.

Singh, R., Mandal, P.K., Singh, A.K., Kumar, R., Sinha, A. (2011b) Coal pillar extraction at deep cover: with special reference to Indian coalfields. Int. Jour. Coal Geol., v.86(2-3), pp.276-288.

Singh, R., Singh, A.K., Maiti, J., Mandal, P.K., Singh, R., Kumar, R. (2011c) An observational approach for assessment of dynamic loading during underground coal pillar extraction. Int. Jour. Rock Mech. Min. Sci., v.45(1), pp.94–804.

Singh, R., Singh, T.N. (1999) Investigation into the behaviour of a support system and roof strata during sublevel caving of a thick coal seam. Geotech. Geol. Eng., v.17(1), pp.21–35.

Venkateswarlu, V., Ghose, A.K., Raju, N.M. (1989) Rock mass classification for design of roof support – a statistical evaluation of parameters. Min. Sci. Tech., v.8, pp.97-107.

Wang, G., Wu, M., Wang, R., Xu, H., Song, X. (2017) Height of the mininginduced fractured zone above a coal face. Eng. Geol., v.216, pp.140-152.

Arun Kumar Singh

Arun Kumar Singh